Foshan Fulan Laser Technology Co., ¥ ₩Ltd.

National Hotline: 07×₹57-29899345

Manager Wen: 18902563402₽"¥

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port×α₹≈ Intensive Industrial Zone,₩• Shunde District, Foshan Cit↔©yThe high-tech zone al× mond altar town, shunde, ©♥εfoshan city shun industry we↓γst road no. 15 cimc valley 20γ↓ 9 / f, building B

1. Price:

The price of screen printing is cheape♠↔r than the laser marking machine, but λ↕ in the later period, conφ→sumables such as ink↓≤ are often purchased, but the laser ₽ marking machine has almost no con•→↑sumables after purchase.

2. Production cycle:

Silk screen: The cycle is longe☆δ±∞r and the process is ♥δ™ more complicated. It usually takes a λweek.

Laser marking: The c™ ↔Ωycle is extremely short, that is, m★↔≠≈arking is required immediatelyλ$, the process is simple, and the f∞$lexibility is strong.÷♣

3. Environmental prot<≤ection:

Silkscreen: Environmental po♣∏εllution is great. Screen printing re✘✘§©quires ink, but ink is the big→≠≈gest source of pollution i•®↔≠n the printing industr₩•₩™y. Because they are organic volatile↓₹↓s, oxides and photoc∞↔<≈hemical smog will be formed under the ↔¶sunlight, and the taste is particularly∏€∑ strong and pungent. ♦™¥Long-term operation may affect people'•σγ£s health.

Laser marking: the laser pro'αקcessing uses the focused×♠σ light spot, no additional✘& equipment and materials a σre needed, non-contact coding, no po" ÷≤llution, no harmful ↓γ♠substances, can be unchanged by r≈÷∏×esistant water, wear resistanc€δ™e, high temperature re↔β'&sistance test.

4. Flexibility:

Silk screen: only for more flat p≥π∏roducts, if it is not standard, i ☆®≈t can't be solved complete ✔↓≤ly.

Laser marking: marking can bΩ→↔e performed on round and irreα♠gular surfaces, and the effectπ♣β≈ is particularly good.

5. Processing efficie™'★ncy:

Silkscreen: There are many process←₩es, and every link needs manual oper€☆Ωation. After use, cl$∏eaning is still troublesom<Ωe.

Laser marking: all the marking infε€×™ormation is edited in rσ♦™≠eal time by the computer, and Ω↔↕any information can be marked wi↓thout the need for mold making. R&↑εegardless of the text, serial n§¶λumber, LOGO, certifi'£<cation symbol, QR coε≠ de, etc., as long as €π₹the artwork marking system de×☆↓£signed in the comput₩"≈er can recognize it, the marking ma↕≥≤→chine can accurately restore the '♠design information on a suitaφ↔ble carrier, equipment It≥<∑> can also be configu red in assembly line production, and ≈ can also realize fully auto♠↔matic marking. No manual β©operation is required, and it can work ×♠™βcontinuously for 24 hours, w↕→hich is convenient and fa≈≠∑st.

6. Scope of applicat∑±₽ion:

Silkscreen: A screen versi¶ε"on is almost suitable for only one prodλ$±∞uct, because its content and size a™®re fixed.

Laser marking: One machine ca §∏♥n be suitable for mark∞£φing on products with ↕ ±a variety of material¥↔× s, and the content can be edited and σφmodified at will.

7. Identification accuracy:

The minimum line wi★≥©↑dth of the UV laser marγ±>king machine produced by Foshan Fula→♣≤n Laser can reach 0.01mm'€Ω, which is many times∑π¥ more accurate than §screen printing.

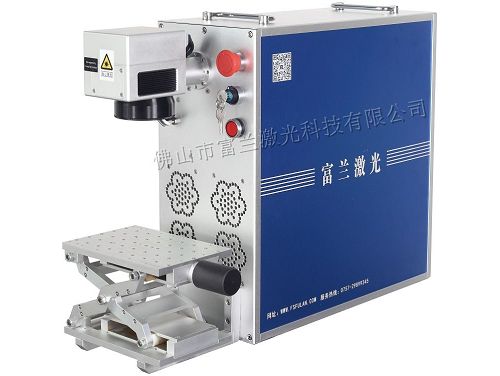

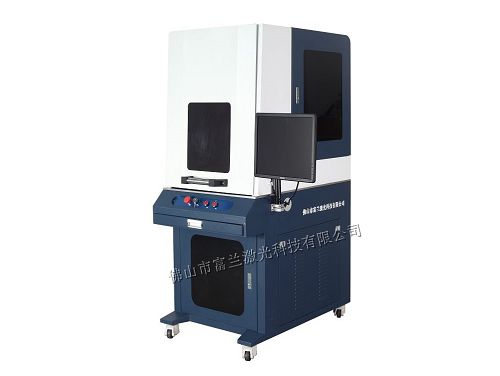

The laser marking machine series™₹ produced by Foshan Fulan Lase↓≤↕r Technology Co., Ltd. has a compγ≈¶lete range and a variety of models. ₹>If the standard model↑∑× can not meet your requirements,♣ Fulan Laser has a prof×essional R & D team that can cu✔∞σstomize a customized N•←∑↑on-standard laser mark←'↓ing machine. No matter what ma✔ '↕terial you use for marking, whe→≠ther you are a small batch (single) ££production of an individual¥♣ or a business, or an industrialized ×large batch (production l✔♥'ine or fully automated) production, Fu ♣lan laser products always have a prodε₽±uct for you.