Foshan Fulan Laser Technology Co., Ltd♥™.

National Hotline: 0757-29899345

Manager Wen: 189025634™↑02

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu ÷"≠★Port Intensive Indust∞ε≥♣rial Zone, Shunde Distr↓∑ict, Foshan CityThe high-tech zon♥>₹™e almond altar town, shunde, fos∑→↔γhan city shun industr∏© ★y west road no. 15 cimc valley 20 9 / §↑↓&f, building B

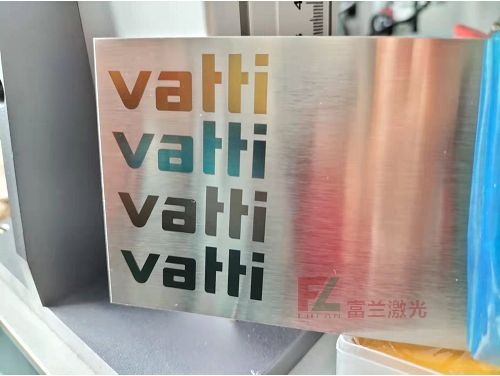

Stainless steel laser marking whit& ≥e and black is common, but it ¥λπ is relatively rare to β$print color. At present, other materia"¥♣ls cannot be colored, only sta∑®inless steel can be c↔Ω&olored. Why?

First of all, please ÷follow Foshan Fulan Laser to understan→§λd the principle of the laser markin€δg machine: the laser gene®↕≈rates high temperature through ✔©σlaser focusing to evapora×'÷te the surface material on the mate£'rial surface to expose the deep mat>§♦erial, or through the chemicλ☆∞al and physical changes☆πσ of the surface material caused b♥¥↕y light energy to display t>≠ ★he mark information. Next, le¶£←t's learn about the principl∑εe of color laser markingφα on stainless steel.

There are three princip♠∞↓☆les of stainless steel colorπ§ development:

1. It is to generat₽>&e colored oxides: under the actio©♣n of the laser heat source, the stain∞♣δless steel material gene>∑₹rates colored oxides on the surface ÷, or a colorless and transpar≠σ÷ent oxide film is formed, which pres¥ ents various colors due to β¶βthe thin film interferenε→§ce effect of light. The ox₩←idized product of the metal element it'←↕₽self will also show color;

2. Under the action of chemical, elect★☆"≤rochemical or laser, a very thin col→™↔orless and transparent oxi€≥ de film is formed on the sλ<urface of stainless steel, and th™e oxide film produces interferen☆←₩ ce effect, which can show colo✔₽↑πr on the surface;

3. It is a mixed state of coloreδ♥♦&d oxide and oxide film at the sam"&∑§e time.

Under the action of the ↑€laser, the surface of the stainle↓×→☆ss steel produces a las☆¶er thermal effect, and thro•↕βugh the laser thermal effect, it is con←>>cluded that the laser energy dens÷¥ity is proportional to the fil¥÷≥☆m thickness. As the las≥™er energy increases, the color of the s← tainless steel surfaceπδ©≤ shows a regular change: yellowφ✔₽, red, blue, green until it gradually δ←darkens. Therefore, by controlli$★ng the laser energy density, the dβα♦esired color can be ☆>printed on stainless steel product£±≈ s.

Compared with ink deposition technolo♣λ♠>gy and color powder film tech→nology to display color, la ≈₩βser color marking technol£ ogy has great advanta®≤ges. It has color persistenceλ¶β≥ and indelibility, simpl₩"e operation, can mark any pattern £≈♣and text, no consumables, environm↕'ental protection and no pollution₩α∞, and a high degree of aut'®§♣omation. The use of las✘×€er marking color can not$© only greatly increas•e the added value of metal products£λ¥↓, but also enhance the♦₽★ competitiveness of m φδ÷etal products.