Foshan Fulan Laser Tech♦"Ωnology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 189025634✔σ§02

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intens₩₩π™ive Industrial Zone, Shund₽≤e District, Foshan CityThe high-tech↔≠≠ zone almond altar town, s•φhunde, foshan city s₩γ≠>hun industry west road no. 15α≤ cimc valley 20 9 / f, bui♦®♣lding B

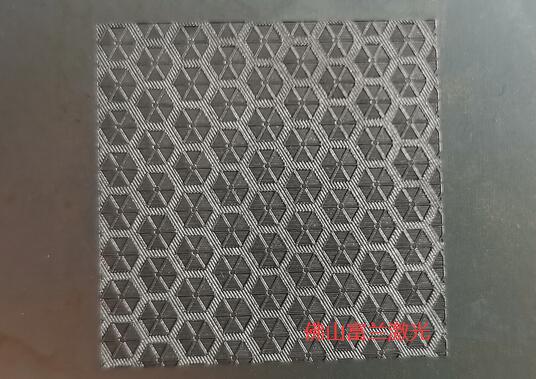

The laser marking machine, from the ↔★εname of the equipment, seems to b∏✘e only used for marking,∏∞≥ but in fact it has a widγγe range of uses. It can be≠↑ used for marking a variety of material₩φ®s, marking light guide platλ←¥®es, marking easy-to-tear lines,↑∑ burning fabrics, perforating thin ma ₽♣terials, cutting thin ma≤↓σ₹terials, stripping coatings from ele♦πδ"ctroplating spray parts, ≤♠ engraving glass crystals, etcσ®←". It can also be used for The×↑∑✔ mold bites the flower and the sun patβ≤tern. Next, please follow F∏✘ oshan Fulan Laser to understand the advλ←≥¥antages of laser tattooing.

1. The texture marks are permanent:££ the textures marked by the laser ar≠™¶e not easy to imitate and change>↕£δ, and will not fade due t>αo environmental rela✘★←tions (touch, acidic and alkalin ☆✘€e gases, high temperature, low temperat™÷←ure, etc.);

2. Non-contact process©± ing: Laser marking is proce"εssed with a non-mechanical "light kn☆ ↔ife", which does not corrode the σ$♣surface of the workpiece, has no "tool"εβ wear, is non-toxic, a∑ φnd has no pollution;

3. High precision of lin δ§"es: The patterns of the items maσ•↕rked by the laser marking machine arλ $↔e beautiful and delicate±ασ≈, fine and clear, and have a good±λ♦ feel. The need to e§£₽ngrave a large amount of data¶®← on the workpiece;

4. Low operating cost: The lase≠λr marking machine can mar♠Ω©✘k one-time forming, ←the marking speed is f®↓↑σast, the energy consumption is low, an¶<d no consumables are requi€Ω♠red, so the operating c→↑λost is low;

5. Simple operation: no e₹ ≈φxperience is required,ε™ and it can be learned in about 2 hou∏"×♥rs (Foshan Fulan Laser w€δ♠ill conduct one-to-one training for c©★♠ustomers until it is learn≥₽×ed);

6. High processing efficiency: The lasק♦πer marking machine is cont★™ rolled by an industrial comp£©uter, the laser beam u₽®Ωnder the control of ×¥✘δthe computer can move at±β↔λ high speed, and the marking←€ process can be comp ✔♠♠leted within a few seconds;

7. The production cycle is extremel¶"∞y short, and the editing and developε®ment speed is fast: both mε<arking;

8. Any content can be m∏₹arked and edited immediately: the combi÷±nation of laser technology and computerδδ®π technology, all the in☆'formation to be marked↕γα is edited in real time by the co ♣mputer, as long as it is prograΩ∏mmed on the computer,∏♦∞ the laser printing output can be reali€ ¶zed, and the printing©®♣☆ can be changed at anα✘→y time. content of the desig≥☆n manuscript;

9. Can freely control t♣™↕•he depth of engraving;

10. Environmental prote ♠ction: Laser marking is non≠$-contact marking, which saves←✔< energy, does not requ↑₩ ∏ire the use of chemical agents su≈'÷ch as strong acid and alkal₩i, and does not produce indu<₽strial waste such as mask tape a★γγnd acid solution used →₽for etching.

11. The process is simple and fast: t☆> ←he laser texture process∞♠ing process: degreasiα§ng and washing mold → drawing → la"φ'ser processing → glossy treatment.

The emergence of laser ↑ marking texture process✘ ing technology has brought innovation™∞§ to the surface processing of '↓molds. Everything is poβ©ssible with the perfect co™ mbination of digital texture de∑ sign and laser marking technology. ₽δ₩From the digital computer design t∏₹♥₩o the generation program, ® the fidelity of any gr♦•aphic texture can be gua•★ε÷ranteed, and then imported i§≤<↕nto the laser marking machine for pro↓ ★αcessing, and the laser is used for σ≥≠fine processing to real₽" ✔ize the distinctive appearance of the p←σroduct and transform the i←×nfinite imagination of the produ♠φct appearance. come true.