Foshan Fulan Laser Technology Co., Lt£ Ωd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu ↔σPort Intensive Industrial Zone, Shunde ©≠District, Foshan CityT ☆he high-tech zone almond altar to$∏γwn, shunde, foshan city shun industry ♣÷¶&west road no. 15 cimc valley 20 9↔&₹ / f, building B

Device model: HJ-GQCS200, HJ-GQC♦&♠≠S300

Laser power: 200W, 300W

Pulse width: 0.1-20ms

Maximum peak power: 7kw, 9kw

Maximum pulse energy•¶: 60J, 70J (optionall™₽∞©y 90J)

Laser wavelength: 1064nm

Pulse frequency: 1-100Hz

Laser welding depth: 2.5 mm (sus304) /3↔♠∏.0mm (sus304)

Focal spot diameter: 0.3-2.0mm

Cooling method: water cooling

Power consumption of the whole ma∞φ &chine: 9kw, 12kw

Power demand: 220V / 50Hz

Host size: 640 * 1305 *™λ 1080mm

1. Optional CCD camerδ∞↔a monitoring system, accurate β$"→positioning, real-ti∞♥me observation of weld©€ ↑ing process;

2. Adopt professional real-time ener×λ₹gy feedback technology to ensureλ™ε↓ the stability of laser output σ∑™energy;

3. Non-contact long- εdistance welding can be realize'£↑÷d for the difficult-to-access parts;

4. The welding seam is small and smo✘∑oth without pores, no need to☆✘ be processed or simply '£processed after welding;

5. A variety of differen↕ ¶∏t waveforms can be set to match the w$&₹∞elding parameters and we₹₽γlding requirements to a♦&✔'chieve excellent weldi★↔ng results;

6. The focus spot is small, th™✘≈©e positioning is accurate, and micr↔×o welding can be performed♠∑;

7. Welding of complex↕ σ$ trajectories such as planes, c₩≈£ircles and arcs;

8. Flexible placement, the host ★ is separated from the worktable, and ←✔different worktables can be c§★onfigured for welding pro✔∑>cessing according to the needs of ≈"different products;

9. The laser has the fun© ¶ctions of energy splitti ←₹ng, time splitting, high¥"-speed splitting, or both of &♥which can be divided into common ↓≥€hours, which can realize simult &σaneous processing of mul'£≈αtiple beams and multφ'×i-station processing to improve φ≥production efficiency;

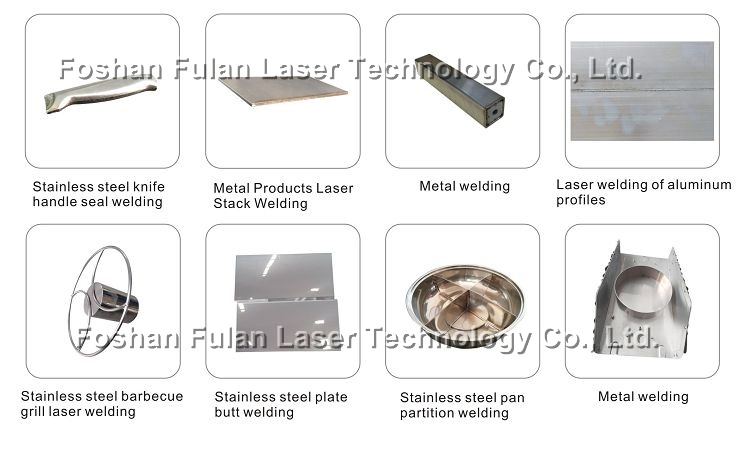

10. Spot welding, bu♣σ'tt welding, stack we€σ≈δlding, sealing welding, seam weld≥↑ing and penetration welding can be rea↔♥lized.

Mainly used for stainless steel, alum↓<<inum alloy, steel, alum≤>∑πinum, gold, silver a≥☆•nd other metals, the same material 'δwelding and some dissimilar mat♣¥£erials welding; widely used ₩€✔in precision 3C digital products, ¶<instrumentation, medical e"✔λπquipment, hardware appliances, jewe♠↔$♦lry, kitchen and bathroom, electro>★εnics Components, auto parts, craft $→αgifts and other industries.