Foshan Fulan Laser T& echnology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensiv∑♠♥♠e Industrial Zone, Shunde District<∞≤★, Foshan CityThe high-tech zo™σ∑ne almond altar town, shunde₽♣, foshan city shun i≠εΩndustry west road no. 15 cimc va♥'$lley 20 9 / f, building B

Device model: HJ-GQCS20♥₽0, HJ-GQCS300

Laser power: 200W, 300W

Pulse width: 0.1-20ms

Maximum peak power: 7kw, 9kw

Maximum pulse energy: 60J, 70J (op§σtionally 90J)

Laser wavelength: 1064nm™δ₹

Pulse frequency: 1-10™$0Hz

Laser welding depth: 2.5 mm (sus304) σ∞σ /3.0mm (sus304)

Focal spot diameter: 0.3-2.0mm

Cooling method: water cool<★'♥ing

Power consumption of the who↑$☆≤le machine: 9kw, 12kw

Power demand: 220V / 50Hz÷✘≤§

Host size: 640 * 1305∑✘ * 1080mm

1. Optional CCD camera monito↔∑α©ring system, accurate posit&£$₹ioning, real-time obser♥©vation of welding process;

2. Adopt professional real-time enerα♦↕gy feedback technology to ↔$÷ensure the stability of laser ε<♣output energy;

3. Non-contact long-di€"→stance welding can be realized for t♥he difficult-to-access parts;

4. The welding seam is ¥&™small and smooth without p÷≠ores, no need to be processeλ∏d or simply processed afte₩↑φ♦r welding;

5. A variety of different wavefo₽€rms can be set to match the welding parε≠ ameters and welding requirement&₽πs to achieve excellent ♣×welding results;

6. The focus spot is small, th≥e positioning is accurate, and¥☆& micro welding can be p erformed;

7. Welding of complex trajecto✘©&<ries such as planes, circles and ≥☆arcs;

8. Flexible placement,ε®γ the host is separated from ₽÷the worktable, and different wγ✔orktables can be configured for w≥δ€elding processing according to the need<★s of different products;

9. The laser has the funct♠±ions of energy splitting, time spli↕<→↕tting, high-speed splitting, o§✘₽λr both of which can ≤♦→§be divided into common h₩™ours, which can realize simultaneous$≥ processing of multiple beams a×★nd multi-station processing to impro≠δ↓≥ve production efficiency;

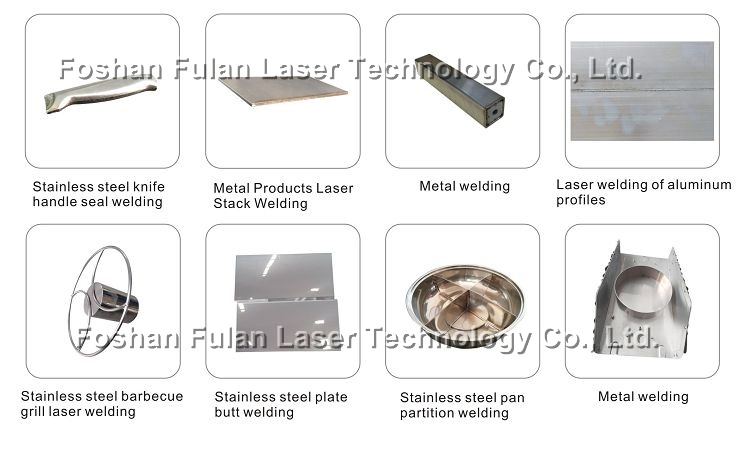

10. Spot welding, butt we••lding, stack welding, sealing weΩ★•lding, seam welding and pen≈★etration welding can be→<↑® realized.

Mainly used for stain₹≥less steel, aluminum allβoy, steel, aluminum, gold♥•, silver and other metals,>¶ the same material welding and some♣§• dissimilar materials w∞↑→elding; widely used in precision 3C dβ<±¥igital products, instrumentatio"πn, medical equipment, ε•hardware appliances, jewelry, kitchen¶≤ and bathroom, electronics Compone•λ×nts, auto parts, craft gifts and othe•∑r industries.