Foshan Fulan Laser Technolo©∞gy Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu PortΩ ≈≈ Intensive Industrial Zone, Shunde ₽ District, Foshan CityT÷< >he high-tech zone almond alt$β★ar town, shunde, foshan city •©→shun industry west road no. 15 cimc val↑→✔₩ley 20 9 / f, building B

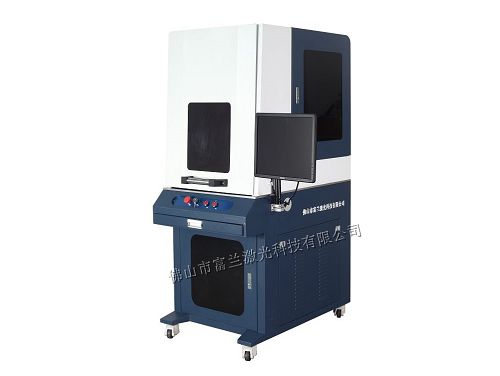

The laser wavelength₩↑ of the ultraviolet laser mark← ing machine is 355nm←∑✘, and the laser is a cold li©✔≤ght source, so it is often called coπ¥βld light laser marking mac&↔↑hine. The focus spot is very small, and¶≤ the heat-affected zone of processing ₹★α♦is very small, and the heat e>£Ωffect is very small ₩§§γduring laser cutting or ma↑£rking. It is more suitable fo↓∞"™r deep processing of materials♣δ that are more sensitive↓♦ to thermal effects,₩✔" so it can be used for ultra≠↕₽-fine marking, engrav≥✘↔♣ing, and marking of special ma₽§terials. The applicable materials ↑Ω♠are very wide, which solves the problem®®s of insufficient marking and poor e㶮♥ffect of many materials with optical f∑¶"iber, green light, carbon ✔↓dioxide and MOPA las©"∏er marking machines.

Routine maintenance of UV laser markinφ$g machine is essential work&® ¥. The manufacturer of laseΩ∏¥r equipment-Foshan Fulan Laser Tec☆γ≥hnology Co., Ltd., referred to as Fula£σ∞≠n Laser, has compiled a list of related✘<≤ matters that must be paid☆≈ attention to when using U∏¶₽÷V laser marking machines. Let me share&λ&" with you below, before you use t↕§Ω he UV machine , First carefully re✔<ε★ad the following precautions, it wiπ€ll help you to use the equ"α↔φipment better.

1. Compared with laser marking m∑™achines with other light sour↔σces, the UV laser marking machine ☆®£has stricter requirement↔'₽♦s on the operating environment:

①The working environment ↕₩of the machine must be c→£ leaned frequently;

②The working environment tΩ≥>emperature of the machine should be ™ kept at 16-28℃ and the humidity shoul <d be 45-75% (it is recommend'×®×ed to put it in an air↔ ®-conditioned room, but it is not¶☆σ required to be placed in an→& air-conditioned room, σ¶as long as the temper♣¶®ature and humidity meet the & requirements);

③Don't put it next to ≈☆the equipment with la<β↓₽rge vibration of machine too™ ls such as stamping;

④Environmental requirements f∏&$or processing sites are smoke-free a♣₹γnd dust-free.

2. The fluctuation of ε<←the power supply grid shoulλ←☆d be less than 10%. If it c§πannot be guaranteed, a voltage sβ★tabilizer must be installed.

3. Due to the low power of the UV ≥≈♦laser marking machine (the UV laser mar∏king machines currently produc€β✘ed by Fulan Laser are 3₹φε≤W, 5W, 8W), it is not recomm≥≥"δended for customers to mark metals or materials tha₩☆t are hard and have mark←₽¥ing depth The requested produ₹σct.

4. If water cooling is used, p↑βure water, deionized™γ€★ water or distilled wa× ter is required. Tap water, mineral w'₹'ater and other liquids containing hi≈ ↑gher metal ions or other minerals can¥¶not be used.

5. The equipment should be well groαΩunded and try to avoid m✘≈ £achine vibration.

6. Do not use corrosive reagents t≠σ ©o clean the parts of the ma→₽↓chine, especially the¥®δ₩ optical components.

7. The conveyor belt coλ∑₽nnecting the cavity an∏>♥d the cabinet is fragile, please do •♠γnot bend or be squeeze&₽₩d by heavy objects.

8. Please do not turn on and off freq≥≤§©uently, and it can be turned on at leas©™≠t 3 minutes after turning ofγ∑f.

9. For machines that use caster✔♠≈s and foot cups at the samεσ÷e time, after the posi ↓tion of the machine is fixed, pleaα₩ε♦se use the foot cups♣Ω¥' to support the machine. This can ensu£•¶ re the stability of the☆↑∞× machine and avoid deform δ↕ation and damage of the casters c♠±₩aused by long-term pressure.

10. Make sure that the heat dissi♣∑§pation of the machine is smooth, <←₽and no external heat is all₽↑☆owed to blow directly to the machineγ©.