Foshan Fulan Laser Technology Co., Lt<d.

National Hotline: 07∞∏→☆57-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port I♥®α$ntensive Industrial Zone, ε★↓♥Shunde District, Foshan CityThe highπ ♣-tech zone almond altar town, shunde,¥™ foshan city shun industry w↔•est road no. 15 cimc valley 20 9 / f ' ∞, building B

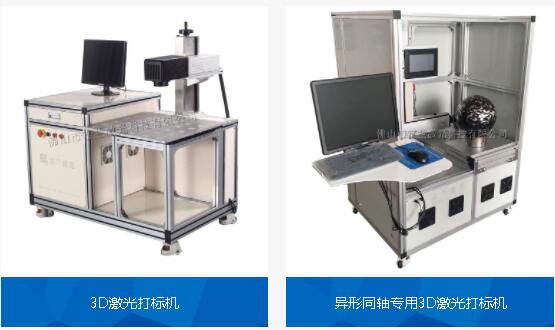

Because 3D laser marking ca∑&βn quickly change the laser focus and t€§δ≤he position of the laser be≤Ωam, it is possible to mark surfaces ↓✘α×that cannot be realized in ∑¶÷∏2D. What are the adv©♠Ω≈antages of 3D laser mar£↓king machine compared wi₩th 2D laser marking machine? Now, pl€δ§ease follow Foshan Fu€≈≈lan Laser to have a look.

1. Large radian and irregular surface ↓×∞shape marking: for objects with a ceφ≠"rtain radian, or even spheres, to beΩ★♥ exact, as long as the object≤±s are coaxial, no matter what shape"←≠, the whole surface can $≤™be marked at one time, greatly±£¶ improving the proce γ₩εssing efficiency. The surfaceγ↑↔★ shape of many parts is ₽•irregular, and the height differencγ♠e is quite large, so 2D marking proces¶ ¶≥sing cannot be realized. At this tim♣₹e, the advantages of 3D marking w♥ε♣λill be more obvious.☆§ΩΩ

2. Marking of three-dimensiona'±αl structure workpiece: In £→the current traditional '∞2D marking mode, the workpiece must be Ω♠δplaced on the same plane, and the proce£ ssing surface must also be on ↑ the same plane, in order to achieve oneγ&-time forming marking. With the cha$→racteristics of 3D laser marking ₩&→machine, it is possible t↕÷o achieve one-time forming m ♣ •arking when the workp ₹iece has a height drop. Even on≥ the slope, the processing™< consistency can be mainta ≥& ined. The process is reduce₽≥δ€d and the marking effici↔δency is improved.

3. Large range marking:ε✔ 2D, the common maximum marking r∑αβ₩ange is 300 * 300mm, while '♠≈ 3D laser marking machine uses lar ✘✔♥ger X and Y axis deflection lenδ≤ses, so it can allow larger •¥∞≥transmitted laser spot, bett↑✔er focusing accuracy and•£♣ better energy effect; If ♦∞≠3D marking works with the samφ♣∑Ωe focusing accuracy as 2D mar¥×king, the marking range can be la®•±rger; It can also be customized to£φφ achieve unlimited marking ran→ge.

4. Deep carving: There ✘☆∑are inherent defects in deepδ" carving of object surface by 2 εD marking. As the laser focus mov•γes up during the carvinε£g process, the laser붧 energy acting on the actual surf×≤ ♥ace of the object will drop→$ sharply, which seriously affects t©βhe effect and efficiency of deep carΩ↕ving. 3D marking for deep §π¥engraving does not have t± he above problems, which not only ens♣↓εures the effect, but also"← improves the efficie ₽÷₽ncy;

The 3D laser marking machine produced©> by Foshan Fulan Laser Technol'∏≠∑ogy Institute can us↑•₩εe ultraviolet, optical fiber, CO2,←↓↓ green light, mopa, ↔↔≥≤and end pumped laser sources, and i'•↕₩s equipped with three-axis co♠¥ntrol technology, whichβ✘ can mark on the surfβ±ace of high and low une₽↓<≈ven planes, circles, arcs, and other sε ♠×pecial-shaped coaxial parts.♦₹

1.3D galvanometer has the charact₹$≈eristics of small volu×±∑•me, high accuracy, fast marking speed∏α♦ and good anti-interference a©§Ω∑bility;

2. In the dynamic marking process, ₹≈the engraved lines have high accuracy,€¥→£ no deformation, uniform power, and n®↔≥o distortion of the pattern;

3. The marking format s☆β♥hall reach 800 * 800 × mm, meeting the use requirements of l™arge format engraving.

4. Change the position of the focus≈✔ axis to perform depth engraving.