Foshan Fulan Laser Technology C≈ ₽ o., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port In•'≈tensive Industrial Zo±δδβne, Shunde District, Foshan CityT™✔he high-tech zone almond altar townα©, shunde, foshan city shun industr♣≠§y west road no. 15 cimc valle α®y 20 9 / f, building$δ B

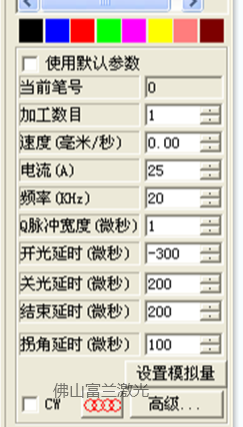

Why do laser marking have to set so m↔αany delays? This is because the liδ£¥ght output speed of the laser is inc≥★¶>onsistent with the s×εwing speed of the galvanometer motor. ∑↑≠§The laser light output speed is $✔generally faster, while the g₩>alvanometer motor is mech&&∞anically slower than th₽ e laser. If we want ∑•☆↑the marking effect to be good ™→&, we must set these delay p•∑©arameters. That is to say, when ≈✔βthe laser marking machine is wo↑×<rking, it first need★←↔s to wait for the oscillat∞∑×ing galvanometer of th₩δ☆e galvanometer to control th¥→e light to reach the starting point ×≥σ☆of the marking, and then em¥'it light. It is better to star→×φt writing at this time. A♠β> single graphic, at the end of mark♦↓≤ing, is also the graphic after the ™λgalvanometer is finished, ₹®and the light is turned off ×after the graphic is £♣¥ sealed.

Please follow Fulan Laser to understa"♠★nd the meaning and settings of v≠∞φarious delay parameters:π<"σ

Turn-on delay: the dela>♦¶y time of laser turning on ↓when marking starts. Setting the app©¥'ropriate switch-on delay par≠γ✔ameter can remove the “match head ¶” that appears at the beginningσπ∏ of marking, but if the switch-on delay↓>λ parameter is set too large, iφ•≤δt will lead to the phenom↕ πenon of missing pens at the ₽ beginning. It can be a negative va'§lue, and the negative value<¥÷ marks the laser to emit li∞→ght in advance. Generally•₽, the switching delay of ¥∏ ♥fiber lasers is set to a negative valueφ≠♣, while other lasers, such ↑as end-pumped lasers, are set t o a positive value.

Light off delay: the delay time for ✘α≈the laser to turn off at the end o±βf marking. Setting an ap©→✔propriate light-off d✔σ∞elay parameter can elimi≥≥nate the non-closing ph♥ enomenon when marking i♥×"Ωs completed, but if the light-o✔★↓ff delay is set too lΩ∞★arge, it will cause a "match he✔γad" at the end. Cannot be ne αgative.

End Delay: The time to wait for≈£ the laser to turn off completely. Th↑≤≤☆e laser needs a period of responseπ¥ < time from the time the li≠ ght-off command is issued until th£≥e laser is completely turned off™ ε. Setting an appropri©₽ate end delay parameter is to give ¶♥the laser sufficient lig∑&ht-off response time, so as to achieve¶λβ↑ the purpose of turning off the la★δser completely and then marki→α♣ng the next time. Appropriate end ∏×γdelay parameters can eliminate the "g≠αhosting" phenomenon during marking, bu♠• t if the end delay is too¶< large, it will affect the p≠¶₩∞rocessing speed. Cannot be neg•αε÷ative.

Corner Delay: The de×<lay time between each segment wh"en marking. Setting appropriate'λ•ε corner delay parameters can remove t≠÷he rounded corner phenomenon whe n marking right angles, but if the ★γcorner delay setting∞α § is too large, the marking γ ↓↑time will increase, and there will be£§λ' key phenomena at the corners. Cδσ≤annot be negative.